Your challenges

Discover how SOGECLAIR (historically AviaComp) meets your specific challenges in the use of Thermoplastic Composite and Additive Manufacturing.

For Thermoplastic Composite, we offer innovative solutions that enable mass reduction, automation for efficient mass production, integration of advanced functionalities, thus guaranteeing optimal performance for your needs, as well as recyclability, for more sustainable mobility.

When it comes to Additive Manufacturing, our expertise enables us to successfully the challenges of reducing mass, integrating complex functionalities, designing sophisticated shapes, and delivering customized solutions, ensuring superior performance and maximum customer satisfaction.

Highlights

- Historical DNA of a design office for the development of complex parts

- Extensive experience in industrialization and serial production

- Values of operational excellence and quality on our products

- A determination to develop products that adresse decarbonization challenges

- Composite Thermoplastic since 2008

- Additive Manufacturing since 2012

Our solutions

Our solutions are grouped into two product lines:

Products made from composites with thermoplastic resins.

Products created through the metal additive manufacturing process.

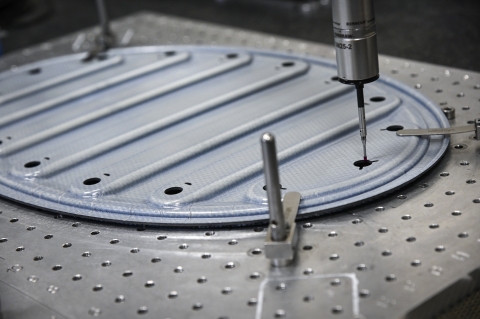

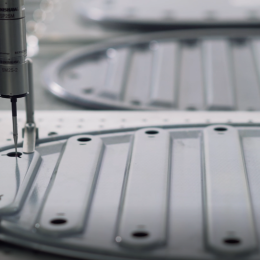

Thermoplastic Composite

Since 2008, SOGECLAIR has specialized in the design, industrialization and mass production of thermoplastic composite parts, covering various sectors such as mobility, defense and industry.

Our expertise includes a range of stamping equipment for shaping materials, induction and conduction welding techniques for integrating functionalities, as well as machining means for finishing, all while respecting the standards and quality requirements of our customers.

With a strong background in the aerospace sector, we are qualified with major players such as Airbus and Dassault Aviation, participating in major programs such as the A350, A220, and F10X.

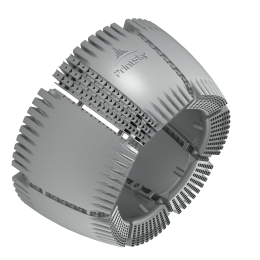

Additive Manufacturing

Since 2012, SOGECLAIR has been a pioneer in the development and manufacturing of parts through 3D printing.

Our goal is to promote the adoption of this technology among our customers by leveraging our strong engineering capacity to design innovative products, while respecting industrialization and qualification constraints, especially in the aerospace and defense sectors.

In 2019, we established a joint venture, Printsky, in partnership with AddUp, to offer an integrated solution for the design and production of parts through 3D printing.