Your challenges

Optimize your industrial processes to meet your production schedules, quality standards, and budget constraints.

We help you define an optimal architecture for your industrial processes that enables the manufacture and delivery of your products, while providing your operational teams with the information and tools they need.

With continuous monitoring and dedicated support, we ensure a high availability rate and constant improvement of your operations.

Our technical and technological solutions are designed to address the challenges of production, markets, and customers.

Highlights

- Multi-year experience in product industrialization

- Recognition of our expertise by major clients and global players

- Multi-skilled teams

- Ability to work with all major flow simulation software and tools

- Cutting-edge cybersecurity and collaborative work infrastructure

- Global presence to ensure proximity and performance

- Economic competitiveness through our offshore centers

- Stability of our skills

- Ability to deploy teams of several hundred engineers on major projects

Our solutions

We are flexible and ready to meet your specific needs. Benefit from our expertise through tailored consulting and service solutions for each project, from customized support to turnkey solutions. Find the perfect solution for your project with us.

Manufacturing engineering

Every step matters in your quest for maximum operational efficiency.

From database creation to industrial architecture, including routing optimization and efficient resource allocation, we offer a comprehensive solution. With precise NC programming, line balancing and M-BOM consolidation, we ensure smooth series production. Our promise: continuous improvement, exemplary work organization, efficient series production, constant enhancement, and simplified work management.

Process

From design to production data analysis, our process solution aims to optimize every stage of your production cycle.

We start with an in-depth analysis of production data, then draw up detailed packages for efficient work management. We also commit to proactive management of action plans aimed at improving your operations, ensuring optimal knowledge management for the continuous growth of your business.

Support for mass production

Optimize your manufacturing process with our dedicated support solution.

When it comes to manufacturing support, we focus on improved rooting, efficient work organisation and effective series production. Additionally, we implement improvements to optimize task transfer and ensure rigorous configuration management to guarantee the consistency and quality of your operations.

Digital and IoT solutions for production

Explore our digital and IoT solutions designed to revolutionize your production process.

By leveraging digitalisation, we define robust data governance, develop intelligent applications, and implement machine learning and artificial intelligence solutions. With Industry 4.0 at the core of our approach, we design advanced architectures and seamlessly integrate them, connect your equipment, and define intuitive human-machine interfaces (HMIs). Finally, we create digital twins for accurate visualization and simulation of your production environment, giving you a complete, real-time view of your process.

Industrial Expertise

Audit and Diagnosis

The transition to a digital industry is guided by a deployment roadmap aligned with your future challenges. Integrating digital solutions requires prior actions: analysis of current processes and procedures, assessment of the company's digital maturity, understanding of your organizational model. Sogeclair supports you in defining your project and in how to deploy it while ensuring change management.

Optimization of Flow Management and Supply Chain

Mastering flows and ensuring the robustness of the supply chain are essential to secure and stabilize the industrial system. Recognizing this, Sogeclair and its partners provide expertise in this area to build the most efficient model.

Knowledge and Expertise Capitalization

One of the keys to continue innovating and growing is to leverage the expertise and know-how acquired over several years. It is evident that this valuable resource is often underutilized or even never formalized. To make this knowledge available, Sogeclair has developed a method to collect all expertise from business and information systems referents and integrate them into our knowledge capitalization tool. This application makes all this information available to project and production teams.

Solutions and Applications

Control and Supervision Applications

To make the right decisions and anticipate all production hazards, Sogeclair develops and deploys visualization and control applications for the various entities within a company. These solutions extract source data from existing IT systems, formalize them, and make them available to each stakeholder according to their role. Each individual has access to their own indicators necessary for managing their activity.

Data Intelligence and AI

Sogeclair develops additional custom applications leveraging multiple existing databases within the company. After undergoing post-processing, these data are integrated into artificial intelligence models enabling more detailed analysis, solution proposals, or predictions.

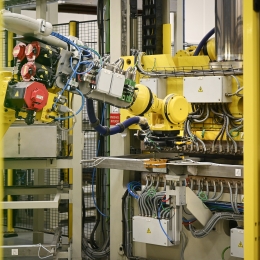

Predictive Maintenance

Machine breakdowns are a significant disruption to production. To prevent corrective maintenance operations, it is essential to implement predictive maintenance solutions. Sogeclair develops applications of this kind, enabling real-time monitoring of equipment deviations to schedule maintenance operations during non-production hours.

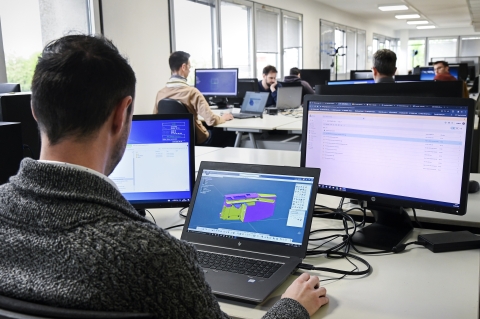

Digital Twin

The digital twin developed by Sogeclair in partnership with Dassault Systèmes is a collaborative tool, customized for each of our users. By integrating data from various IT systems and modeling processes and procedures, this digital twin incorporates specific functionalities for each industrial player to address their own challenges and issues.

These functionalities enable the simulation of various operations and behaviors of the production system by varying different parameters. Thus, the industrial player has a tool to design or adapt their production system in anticipation of various contingencies. Several functionalities have been developed to address different use cases: layout validation, flow simulation, work sequences, ergonomics, energy consumption, etc.

The digital twin integrates all data, models, and functionalities on a single collaborative platform, accessible to all stakeholders, ensuring data sharing based on a common repository and interoperability. Sogeclair develops and deploys your digital twin and provides training for the teams.